1. Reliability

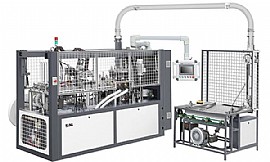

Our JBZ-12H middle speed paper cup forming machine appears with high

performance, high efficiency and high quality. Outfitted with integrated

steel plate machine body and oil spraying lubrication system, our

paper cup machine keeps long-term normal and steady operation.

2. High efficiency and energy conservation

Advanced high-precision cylindrical cam driving unit with gear drive

system ensures precise forming at every station. Servo tracking system

for bottom paper feeding fixes the size of bottom paper to save raw

materials effectively.

3. Foreign technology and domestic manufacture

The cup bottom is processed by Switzerland Leister heating system

through 2 steps flameless heating. Moreover, every production procedure

is detected by Japan Omron photoelectric device and will be reported.

4. User-friendly design

Under the control of PLC system through human-computer interface, our

middle speed paper cup forming machine keeps long term stable

operation. Manual operation can be replaced by automatic paper cup

counting and collecting table with appropriate setting.

High Speed Paper Cup Forming Machine Machine Structure

| 1.Paper holder | 2.Paper fan preheating | 3.Ultrasonic | 4.Cup pipe |

| 5.Cup turnplate | 6.Bottom punching | 7.Bottom paper preheating 1 | 8.Bottom paper preheating 2 |

| 9.Bottoman paper folding | 10.Bottom knurling | 11.Cup curling | 12.Top curling 1 |

| 13.Top curling 2 | 14.Cop output | 15.Bottom feeding 1 | 16.Bottom feeding 2 |

High Speed Paper Cup Forming Machine Main Advantages:

| Fine grinding machine body, first-step hot air heating system and Unique welding head design make sure the stabile, fast and long-term machine running. | Different from traditional iron mould, our machine is using aluminum alloy moulds, more durable, and no pollution to the cups. | Two Leister heaters are used for cup bottom sealing, highly increase the heating effect and ensure the good quality of knurling. |

| The whole cup producing process is detected by photoelectric detectors. They will stop the machine once any problem happens. | Double knurling system ensures you can get really nice and good quality cups. | Siemens brand PLC control system, good quality and excellent performance. |

High Speed Paper Cup Forming Machine Specification

| Model | JBZ-12H |

| Cup size | 6~16oz, (Outer diameter of cup rabbet 60~100mm, Outer diameter of cup bottom 50~70mm, Cup height 60~135mm, Bottom depth 5~10mm) |

| Rated power | 90-120pcs/min |

| Total power | 19KW |

| Actual power | 10.5KW |

| Air Pressure | 0.6m3/min;0.6MPa(provided by customer) |

| Applicable raw paper | 190~350g/m2 (single/double-sided PE coated paper) |

| Machine weight | 3800Kg |

| Machine packing size | 2700×1500×1800mm |

| Collector packing size | 1150×850×1800mm |

Note: The thickness of paper's PE coating should not less than 15g/m2

rese arch and develop new products like single coating film paper cup forming machine, paper bowl. forming machine, paste bowl machine, disk box machine...