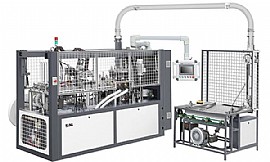

Model: JBZ-12H

High Speed Paper Cup Forming Machine Machine Structure

| 1.Paper holder | 2.Paper fan preheating | 3.Ultrasonic | 4.Cup pipe |

| 5.Cup turnplate | 6.Bottom punching | 7.Bottom paper preheating 1 | 8.Bottom paper preheating 2 |

| 9.Bottoman paper folding | 10.Bottom knurling | 11.Cup curling | 12.Top curling 1 |

| 13.Top curling 2 | 14.Cop output | 15.Bottom feeding 1 | 16.Bottom feeding 2 |

High Speed Paper Cup Forming Machine Main Advantages:

| Fine grinding machine body, first-step hot air heating system and Unique welding head design make sure the stabile, fast and long-term machine running. | Different from traditional iron mould, our machine is using aluminum alloy moulds, more durable, and no pollution to the cups. | Two Leister heaters are used for cup bottom sealing, highly increase the heating effect and ensure the good quality of knurling. |

| The whole cup producing process is detected by photoelectric detectors. They will stop the machine once any problem happens. | Double knurling system ensures you can get really nice and good quality cups. | Siemens brand PLC control system, good quality and excellent performance. |

High Speed Paper Cup Forming Machine Specification

| Model | JBZ-12H |

| Cup size | 6~16oz, (Outer diameter of cup rabbet 60~100mm, Outer diameter of cup bottom 50~70mm, Cup height 60~135mm, Bottom depth 5~10mm) |

| Rated power | 90-120pcs/min |

| Total power | 19KW |

| Actual power | 10.5KW |

| Air Pressure | 0.6m3/min;0.6MPa(provided by customer) |

| Applicable raw paper | 190~350g/m2 (single/double-sided PE coated paper) |

| Machine weight | 3800Kg |

| Machine packing size | 2700×1500×1800mm |

| Collector packing size | 1150×850×1800mm |